To guarantee a spark plug on a dirt bike, first, prepare safety gear like gloves and safety glasses. Next, remove the spark plug wire carefully using a spark plug socket and ratchet. Inspect the old plug for damage. Handle the wire delicately to prevent harm. Unscrew the old spark plug and check it for wear or damage. Remember to adjust the gap and apply anti-seize compound before installing the new plug securely. Finally, don't forget the importance of using a dielectric spark plug boot protector. Following these steps guarantees proper maintenance of your dirt bike's spark plug system.

Key Takeaways

- Prepare safety gear like gloves and safety glasses.

- Inspect old spark plug for wear or damage.

- Use proper tools to remove and install spark plug.

- Check and adjust spark plug gap if necessary.

- Securely reconnect spark plug wire after replacement.

Safety Gear Preparation

Get your safety gear ready, including gloves and safety glasses, to shield your hands and eyes from dirt and debris while replacing the spark plug on your dirt bike. Before installing the new spark plug, it's important to check the gap to ensure peak performance.

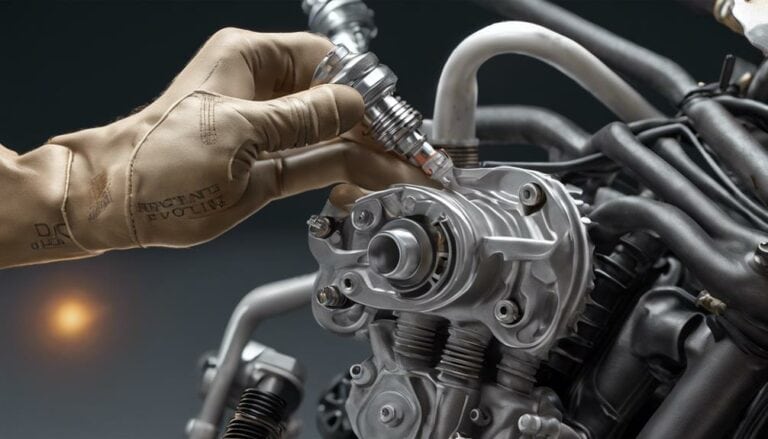

Start by removing the spark plug wire using a spark plug socket and ratchet, ensuring a firm grip to prevent stripping. Next, locate the spark plug on the engine and use the spark plug socket to carefully loosen and remove the old spark plug.

Inspect the old spark plug for any signs of damage, such as fouling or wear, which could indicate underlying issues with the engine. Once the old spark plug is removed, carefully insert the new spark plug by hand to avoid cross-threading, then tighten it using the spark plug socket and ratchet.

Make sure the spark plug is securely in place to prevent any issues during engine operation.

Disconnect the Spark Plug Wire

Inspect the spark plug wire for any signs of damage before gently pulling the boot covering the spark plug terminal. It's important to handle the wire carefully to avoid any harm.

Here are some key points to keep in mind when disconnecting the spark plug wire:

- Handle with Care: Treat the spark plug wire delicately to prevent any damage to the wire or the connection.

- Inspect for Damage: Before removal, check the wire for any wear or damage that might necessitate a replacement.

- Keep Clean: Make sure the wire is free of dirt and debris to maintain a solid electrical connection.

- Secure Reconnection: After replacing the spark plug with a new one, reconnect the spark plug wire securely to guarantee proper functionality.

Remove the Old Spark Plug

When removing the previous spark plug from your dirt bike, make sure you carefully use a spark plug socket and a wrench to unscrew it from the cylinder head. This process guarantees that the spark plug is removed without causing any damage to the surrounding components. Once the old spark plug is successfully removed, it's time to prepare for the installation of a new one. Below is a table outlining the steps involved in removing the old spark plug:

| Steps to Remove Old Spark Plug |

|---|

| 1. Disconnect the spark plug wire to prevent electrical damage. |

| 2. Use a spark plug socket and a wrench to unscrew the old spark plug. |

| 3. Inspect the previous spark plug for signs of wear, such as fouling or deposits. |

| 4. Decide whether to clean and regap the old spark plug or replace it with a new one. |

Following these steps will ensure a smooth change from the old spark plug to a new one, maintaining the best performance of your dirt bike.

Inspect the Old Spark Plug

Upon examining the old spark plug, make sure to thoroughly assess for any visible signs of fouling, wear, or damage that may impact its performance. It's essential to inspect the electrode and note the color of the spark plug to gain insight into the engine's running condition. Here are some key points to take into account during the inspection:

- Look for signs of fouling, such as sooty deposits or oil on the spark plug

- Check the electrode for wear, corrosion, or damage

- Note the color of the spark plug to determine the engine's running condition

- Compare the old spark plug's condition to manufacturer specifications for replacement guidance.

Check and Adjust Gap

To guarantee peak engine performance, employ a gapping tool to inspect and adjust the gap between the electrode and metal part of the spark plug. The gap is a critical aspect of the spark plug as it affects the ignition and combustion process within the engine.

Using the gapping tool, carefully measure the distance between the center electrode and the ground electrode. If the gap doesn't meet the manufacturer's specifications, adjust it by gently bending the ground electrode using the tool's arms. It's essential to make sure that the gap is within the recommended range to prevent misfires, poor engine performance, and potential damage.

A correctly adjusted gap promotes efficient spark plug function, leading to efficient combustion and overall engine operation. Make any necessary adjustments with precision to maintain the spark plug's effectiveness. Following the manufacturer's guidelines for the spark plug gap adjustment is crucial for ensuring the dirt bike's engine runs smoothly and efficiently.

Apply Anti-Seize Compound

When applying anti-seize compound on the spark plug's threads, make sure to apply a thin, even coating to prevent corrosion and facilitate future removal.

Avoid excessive application, as it can hinder the spark plug's conductivity.

Using anti-seize compound is vital for maintaining the spark plug's integrity and ensuring easy removal when needed.

Prevents Metal Corrosion

Applying anti-seize compound on the spark plug threads safeguards against metal corrosion and seizing, ensuring easier future removal and enhancing longevity. This compound acts as a shield, protecting the threads from deteriorating due to exposure to moisture and other environmental factors.

Here are four reasons why applying anti-seize compound is essential:

- Forms a protective barrier on the spark plug threads.

- Facilitates effortless removal of the spark plug during future replacements.

- Maintains a secure seal and prevents moisture-induced rust.

- Particularly beneficial in high humidity or water-exposed settings.

Enhances Future Removal

Enhance future spark plug removal efficiency by wisely applying anti-seize compound to the threads. Anti-seize compound acts as a lubricant and barrier, reducing the likelihood of thread galling and corrosion.

When exposed to high-heat environments like motorcycle engines, this compound maintains the integrity of the threads, ensuring easy removal of the spark plug in the future.

It's important to apply a small amount of anti-seize compound evenly on the threads to prevent excessive buildup that could interfere with the spark plug's performance.

Install the New Spark Plug

To properly install the new spark plug, follow these steps:

- Ensure the spark plug gap matches the manufacturer's specifications.

- Screw the spark plug in by hand to prevent cross-threading before tightening it securely using a spark plug socket.

- Use a torque wrench to achieve the recommended torque specification for best performance.

Properly Gap Spark Plug

Verify the correct gap on the new spark plug is confirmed using a gapping tool, as specified in the owner's manual. After checking the gap, follow these steps to properly install the spark plug:

- Adjust the gap using the tool's arms to match the manufacturer's recommendations.

- Apply a thin layer of anti-seize compound on the spark plug threads.

- Carefully screw the new spark plug in by hand to avoid cross-threading.

- Utilize a torque wrench to tighten the spark plug to the specified torque setting.

Remember to contemplate using a dialectic spark plug boot protector for added protection against moisture and to maintain a reliable electrical connection.

Securely Tighten Spark Plug

Secure the new spark plug by turning it by hand until it's snug in the cylinder head. Once snug, use a torque wrench to tighten the spark plug to the manufacturer's recommended torque specification. Make sure not to over-tighten the spark plug; a little bit of resistance after it's snug is essential. Over-tightening can damage the threads or cylinder head.

Ensuring the spark plug is securely seated and properly torqued is vital for top performance. Additionally, apply dielectric grease to the spark plug boot to prevent moisture and guarantee a good electrical connection. By following these steps, you can rest assured that your spark plug is securely installed and ready to deliver reliable performance on your dirt bike.

Secure With Proper Torque

When securing the spark plug with proper torque, make sure the washer touches the cylinder head for accurate seating. It's essential to adhere to specific guidelines to guarantee the spark plug is secured correctly without causing any damage.

Here are some vital steps to secure the spark plug with proper torque:

- Turn the spark plug until the washer touches the cylinder head to seat it accurately.

- For an old spark plug, turn an additional eighth to a quarter of a turn for secure seating.

- With a new spark plug, turn half a turn after seating to confirm proper torque.

- Avoid over-torquing to prevent damaging the cylinder head or the spark plug.

Use a Dialectic Spark Plug Boot Protector

To guarantee peak performance and longevity of your dirt bike's spark plug system, it's essential to use a dialectic spark plug boot protector.

When applying the protector, make sure to fully cover the spark plug boot to create a dependable barrier against moisture and contaminants.

Importance of Boot Protection

For optimal performance and longevity of your dirt bike's spark plug, using a dialectic spark plug boot protector is essential. This protector plays a vital role in safeguarding your spark plug from moisture, ensuring electrical integrity and enhancing spark plug longevity.

Here are the key reasons why boot protection is important:

- Moisture Protection: Prevents moisture from causing electrical issues.

- Electrical Integrity: Maintains a secure and dry connection.

- Spark Plug Longevity: Prolongs the life of the spark plug.

- Reliable Ignition: Guarantees reliable engine performance and ignition.

Installation Tips and Tricks

To guarantee proper installation of a dialectic spark plug boot protector, carefully slide the protector over the spark plug terminal until it securely covers the connection.

When installing the protector, make sure it fits snugly to prevent any moisture or debris from entering and interfering with the spark plug's performance. Important installation techniques involve pushing the protector gently but firmly onto the terminal, ensuring it forms a tight seal.

This maintenance strategy is essential for safeguarding your spark plug and electrical system. If you encounter any issues during installation, troubleshoot by checking the fit and alignment of the protector.

Following these steps diligently will help maintain a reliable connection and extend the life of your spark plug.

Benefits of Using Protector

Invest in a dialectic spark plug boot protector to enhance the durability and performance of your dirt bike's spark plug system. This protector offers multiple benefits, including:

- Maintenance Tips: Prevents moisture from entering the spark plug connection, reducing the risk of corrosion and electrical issues.

- Performance Enhancement: Adds an additional layer of protection to the spark plug wire, ensuring a reliable electrical connection for peak engine performance.

- Weather Protection: Guards the spark plug system against water, mud, and other elements, extending the spark plug's lifespan.

- Simplicity: Investing in a dialectic spark plug boot protector is an easy and effective way to maintain your dirt bike's spark plug system integrity.

Test and Monitor the Dirt Bike

After replacing the spark plug on your dirt bike, evaluate its performance by testing and monitoring key indicators such as idling, acceleration, exhaust emissions, and overall engine behavior.

Start by testing the dirt bike's engine, guaranteeing smooth idling and responsive acceleration. Monitor the exhaust for any abnormal smoke or odors, which could indicate spark plug issues.

During rides, observe consistent power delivery to identify any misfires, rough running, or starting difficulties that may suggest faulty installation. Keep an eye on fuel consumption and engine temperature to gauge overall efficiency post-replacement.

If any issues arise, engage in diagnostic troubleshooting to pinpoint the problem promptly.

Conclusion

To sum up, replacing a spark plug on a dirt bike is a straightforward task that can greatly enhance the performance of your machine. By following these steps, you can guarantee that your dirt bike is running efficiently and safely.

For instance, envision a rider effortlessly speeding through muddy trails after replacing a worn spark plug, feeling the power and responsiveness of their bike renewed.

Don't overlook this important maintenance task for peak dirt bike performance.