To verify the condition of a dirt bike's wiring harness, visually examine for damage, melted insulation, and secure connectors. Utilize a multimeter to test for continuity and resistance. Inspect wire integrity for fraying, cuts, burns, and adequate insulation. Evaluate connections for security and correct voltage. Regularly check to prevent electrical issues and enhance performance. Confirm smooth operation by validating proper routing, secure attachment, and minimizing interference risks. These steps will help maintain your dirt bike's electrical reliability.

Key Takeaways

- Visual inspection for damage, melted insulation, and secure connectors.

- Multimeter testing for continuity, resistance, and faulty connections.

- Checking continuity with a multimeter to identify breaks or shorts.

- Assessing wire integrity for fraying, cuts, burns, and proper insulation.

- Examining connections for secure attachment, continuity, and proper voltage.

Visual Inspection

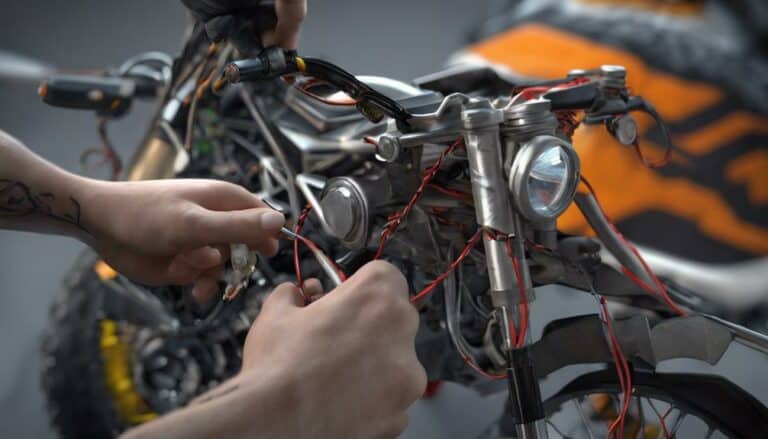

Examine the dirt bike's wiring harness visually for any visible signs of damage or irregularities that may impact its performance or safety. Look closely for frayed wires, melted insulation, or exposed connections that could pose a risk. Confirm all connectors are securely attached to prevent electrical issues that may affect the bike's battery.

Make sure there are no loose or disconnected components that could disrupt the electrical system's functioning. Additionally, check for any signs of water or moisture damage that could lead to corrosion, jeopardizing the wiring's integrity. Verify that all wires are correctly routed and fastened to avoid chafing or rubbing against other parts, which could cause damage over time.

Pay attention to any burnt or discolored areas on the wiring, as they may indicate potential overheating or short circuits that need immediate attention. By thoroughly examining the wiring harness, you can maintain the bike's electrical system and ensure a safe and top-notch riding experience.

Multimeter Testing

When checking a dirt bike's wiring harness, utilize a multimeter set to ohms to evaluate continuity and resistance in the electrical connections. Before starting the test, make sure the bike's battery is fully charged or running to provide accurate readings.

Begin by disconnecting the wiring harness from the bike's electrical components. Set your multimeter to the ohms setting and touch the probes to each end of a wire within the harness. A reading close to zero indicates good continuity, while a high reading suggests a break in the wire. Repeat this process for each wire in the harness to identify any faulty connections.

Additionally, measure the resistance in the wires to ensure they're within the specified range. Look out for any discrepancies that may indicate damaged wires. By conducting thorough multimeter testing, you can pinpoint any electrical issues within the wiring harness and address them promptly for best dirt bike performance.

Checking Continuity

To validate the integrity of a dirt bike's wiring harness, utilize a multimeter set to the continuity function to confirm the uninterrupted flow of electrical current throughout the connections. This process involves disconnecting the wiring harness from the components and testing continuity between specific points to identify any breaks or shorts. A continuous beep or low resistance reading indicates a solid connection, while no beep or high resistance signals an issue. Inspect the wiring visually for any visible damage, fraying, or wear that may suggest a potential problem with continuity. Testing continuity in the wiring harness helps guarantee proper electrical flow and can prevent issues such as electrical shorts or component failures.

| Keywords | Details |

|---|---|

| Corrosion Prevention | Check for rust or corrosion |

| Wire Insulation | Confirm insulation is intact |

| Wire Gauge | Verify correct wire thickness |

| Voltage Drop | Confirm minimal voltage drop |

| Wire Routing | Check for appropriate routing |

| Waterproof Connectors | Confirm connectors are water-resistant |

Assessing Wire Integrity

Examine the wiring harness meticulously for any visible signs of fraying, cuts, or burns that could indicate underlying issues.

Confirm the wires have proper insulation to prevent short circuits and electrical interference.

Use a multimeter to thoroughly test wire continuity, checking for breaks or loose connections within the harness.

Visual Inspection for Cuts

Regularly scan the entirety of the wiring harness for any visible cuts, abrasions, or fraying to evaluate the integrity of the wires. Identifying and repairing damaged wires promptly is essential to prevent future problems. Below is a table highlighting key points to take into account during the visual inspection process:

| Visual Inspection Tips | Description | Importance |

|---|---|---|

| Check for Cuts | Look for any visible breaks or nicks in the wires. | Vital for wire integrity |

| Assess for Abrasions | Examine the harness for signs of rubbing or scraping. | Helps prevent short circuits |

| Look for Fraying | Inspect for unraveling or splitting of wire strands. | Indicates potential issues |

Check for Fraying

Scan the wiring harness thoroughly for any visible signs of fraying, as this can indicate wear and potential damage that may impact the dirt bike's electrical system. To guarantee fraying, consider using wire protection such as loom or conduit in areas prone to rubbing.

Inspect for insulation damage caused by heat exposure, which can compromise wire integrity. Focus on checking rubbing areas where wires may come into contact with other components. Fraying can lead to shorts and electrical malfunctions. Address any fraying promptly to maintain the integrity of the wiring harness.

Proper maintenance and fraying prevention measures will help secure the longevity and performance of your dirt bike's electrical system.

Test Wire Continuity

To assess the integrity of the wiring, utilize a multimeter set to continuity mode to verify the wires are unbroken and functional. Connect one probe to a wire end and the other probe to the opposite end to test for a continuous path. Lack of continuity suggests a break in the wire, necessitating repair or replacement.

Check for physical damage, corrosion, or fraying along the wire length as potential indicators of issues. Resistance testing through continuity mode aids in ensuring proper electrical connections and the functioning of the dirt bike's components.

Examining Connections

Are the wiring harness connections on your dirt bike free from corrosion, damage, or loose fittings that could disrupt electrical flow? Checking for importance, guarantee is vital to make sure secure connections and functionality.

Start by visually inspecting all connection points for any signs of wear, corrosion, or loose terminals. Make sure each connector is firmly plugged in and that the terminals are clean to guarantee best conductivity.

Evaluating wiring stability, durability is essential to prevent potential electrical failures. Utilize a multimeter to test for continuity and proper voltage at different locations along the wiring harness. Look out for any fraying, melting, or exposed wires that could result in short circuits or other issues.

Conduct a wiggle test while the bike is running to detect intermittent connection problems that may arise. By meticulously examining and maintaining your dirt bike's wiring connections, you can enhance its electrical performance and overall reliability.

Addressing Corrosion

How can you effectively address and prevent corrosion in the wiring harness of your dirt bike for excellent electrical performance and reliability?

- Corrosion Prevention: Regularly inspect the wiring harness for any signs of corrosion, such as greenish-blue deposits or rusty connectors. Early detection can help prevent major issues down the line.

- Corrosion Impact on Performance: Corrosion can disrupt the flow of electricity within the wiring harness, leading to electrical problems in your dirt bike. Ensuring a corrosion-free harness is essential for peak performance.

- Corrosion Mitigation for Reliability: Use a wire brush or fine sandpaper to gently clean off any corrosion on the connectors and terminals. Applying a dielectric grease after cleaning can help prevent future corrosion, ensuring good electrical connections and improving the overall reliability of your dirt bike.

Preventing Electrical Issues

Examining the wiring harness regularly is important to prevent electrical issues in your dirt bike. To avoid shorts and failures, inspect the harness for any fraying, damage, or exposed wires that could compromise its integrity.

Utilize a multimeter to test continuity and guarantee proper connections, reducing the risk of intermittent problems. Properly route and secure the harness to prevent chafing, rubbing, or pinching that may lead to damage over time.

Check for corrosion, moisture intrusion, or water damage, as these can cause electrical malfunctions. To maintain electrical conductivity, clean and inspect connections, terminals, and plugs regularly.

Ensuring Smooth Operation

To guarantee smooth operation of your dirt bike, thoroughly inspect the wiring harness for any physical damage or improper routing that could result in electrical malfunctions. Follow these essential steps to make sure your dirt bike operates at its best:

- Preventing Malfunctions: Regularly check for physical damage like cuts, abrasions, or exposed wires that may lead to electrical issues.

- Ensuring Safety: Confirm the proper routing and secure attachment of the wiring harness to prevent interference with moving parts or heat sources, reducing the risk of accidents.

- Enhancing Performance: Test the continuity of the wiring harness with a multimeter to make certain no breaks or short circuits exist, optimizing electrical flow for improved performance.

Conclusion

To wrap up, by regularly performing visual inspections, using a multimeter to test for continuity, checking wire integrity, examining connections, addressing corrosion, and taking preventative measures, you can guarantee the smooth operation of your dirt bike's wiring harness.

Remember, just like a well-maintained engine keeps a bike running smoothly, a properly maintained wiring harness is essential for peak performance on the trails.

Stay ahead of potential issues and enjoy trouble-free rides with a reliable electrical system.